最新刊期

期 4 , 2023

-

摘要:Due to the excessive exploitation of fossil fuels, it has led to serious energy crises and environmental ecological issues, making the research of green power generation materials increasingly important. Wood, as a widely available and renewable resource, has abundant reserves worldwide. In recent years, generating power from wood has emerged as a new strategy to combat the energy crisis. This paper mainly introduces three kinds of wood power generation technologies and power generation mechanisms: piezoelectricity, triboelectric nano-power generation and hydrovoltaic power generation, analyzes the impact of modification technologies on wood power generation performance, summarizes the current advantages and application scenarios of wood as a green power generation material device, and discusses the prospects and challenges of wood power generation technology are prospected.关键词:wood;piezoelectric power generation;triboelectric nano power generation;hydrovoltaic power generation;cellulose crystal;power generation device

摘要:Due to the excessive exploitation of fossil fuels, it has led to serious energy crises and environmental ecological issues, making the research of green power generation materials increasingly important. Wood, as a widely available and renewable resource, has abundant reserves worldwide. In recent years, generating power from wood has emerged as a new strategy to combat the energy crisis. This paper mainly introduces three kinds of wood power generation technologies and power generation mechanisms: piezoelectricity, triboelectric nano-power generation and hydrovoltaic power generation, analyzes the impact of modification technologies on wood power generation performance, summarizes the current advantages and application scenarios of wood as a green power generation material device, and discusses the prospects and challenges of wood power generation technology are prospected.关键词:wood;piezoelectric power generation;triboelectric nano power generation;hydrovoltaic power generation;cellulose crystal;power generation device- 289

- |

- 73

- |

- 0

发布时间:2023-10-07

REVIEWS

-

摘要:Machine vision technology can realize rapid and non-contact detection of object size, and can replace the manual measurement method for furniture panels, so as to improve the efficiency, increase the detection speed, smooth the production continuity, and so on. In this study, a laser line-array camera combined with line-structured light measurement technology was used to build an online measurement system for furniture panels. The measurement accuracy and efficiency of machine vision technology were studied and analyzed. When the furniture panel moves at 300 mm/s uniformly on the transmission device and passes through the laser triangle plane irradiated by the 650 nm laser, the LASER reflected on the surface of the furniture panel is imitated by the CMOS sensor. After calibration with sawtooth target method, machine vision software Halcon is used to read the camera calibration file. The images of furniture panels are generated by the laser camera. After image processing technology, the dimensions of furniture panels in three directions of thickness, width, and length are detected respectively. The high-precision measurement of the furniture panel’s three dimension is realized. The results showed that the maximum deviation ratios of thickness, width, and length of furniture panels measured by the system compared to manual measurement were 3.6%, 0.5% and 0.1%, respectively. The maximum difference in thickness was less than the IT15 level tolerance value (<0.70 mm), the maximum difference in width was less than the IT14 level tolerance value (<1.00 mm), and the maximum difference in length was less than the IT12 level tolerance value (<0.90 mm), according to the industry standard QB/T 4452—2013 Wood furniture Limits and fits. The measuring time for a single piece was shortened from 30.1 seconds to 5.5 seconds, indicating the advantages of good measurement accuracy and efficiency of the system.关键词:three-dimensional measurement for furniture panels;machine vision;linear structure light;camera calibration;image processing

摘要:Machine vision technology can realize rapid and non-contact detection of object size, and can replace the manual measurement method for furniture panels, so as to improve the efficiency, increase the detection speed, smooth the production continuity, and so on. In this study, a laser line-array camera combined with line-structured light measurement technology was used to build an online measurement system for furniture panels. The measurement accuracy and efficiency of machine vision technology were studied and analyzed. When the furniture panel moves at 300 mm/s uniformly on the transmission device and passes through the laser triangle plane irradiated by the 650 nm laser, the LASER reflected on the surface of the furniture panel is imitated by the CMOS sensor. After calibration with sawtooth target method, machine vision software Halcon is used to read the camera calibration file. The images of furniture panels are generated by the laser camera. After image processing technology, the dimensions of furniture panels in three directions of thickness, width, and length are detected respectively. The high-precision measurement of the furniture panel’s three dimension is realized. The results showed that the maximum deviation ratios of thickness, width, and length of furniture panels measured by the system compared to manual measurement were 3.6%, 0.5% and 0.1%, respectively. The maximum difference in thickness was less than the IT15 level tolerance value (<0.70 mm), the maximum difference in width was less than the IT14 level tolerance value (<1.00 mm), and the maximum difference in length was less than the IT12 level tolerance value (<0.90 mm), according to the industry standard QB/T 4452—2013 Wood furniture Limits and fits. The measuring time for a single piece was shortened from 30.1 seconds to 5.5 seconds, indicating the advantages of good measurement accuracy and efficiency of the system.关键词:three-dimensional measurement for furniture panels;machine vision;linear structure light;camera calibration;image processing- 69

- |

- 12

- |

- 0

发布时间:2023-10-07

EMPOWER INTELLIGENT HOME MANUFACTURING WITH TECHNOLOGIES

-

摘要:In order to study the effect of bolt arrangements on the mechanical properties of bolted glulam joints with slotted-in steel plates, monotonic loading tests were carried out on beam-column joints and beam joints in square and stagger bolt arrangements. The failure mode and failure mechanism were studied. The stiffness, ductility, and bearing capacity of these joints were analyzed through the bending moment-rotation and load-displacement curves. The test results indicate that in addition to the low stiffness phase when the bolt contacts the screw hole at the initial loading stage, the stress process of bolted glulam joints were divided into elastic, crack, and failure stages. The staggered arrangement of bolts improve the bending and tensile bearing capacity and ultimate deformation of beam-column joints and beam joints: the yield bending moment and tensile yield load increase by about 35% and 7.1% respectively, compared to the beam-column joints and beam joints in square bolt arrangements. For the staggered bolted joints, the deformation of beam-column joints in the plastic stage is small. The ductility coefficient is about 71% of that of the squared bolted beam-column joints. The staggered bolted beam joints have better plastic deformation and ductility. The tensile ductile coefficient is 2.79 times that of squared bolted beam joints.关键词:glulam;beam-column joints;beam joints;slotted-in steel plate;bolted connection;loading capacity;rotational behavior;failure mode

摘要:In order to study the effect of bolt arrangements on the mechanical properties of bolted glulam joints with slotted-in steel plates, monotonic loading tests were carried out on beam-column joints and beam joints in square and stagger bolt arrangements. The failure mode and failure mechanism were studied. The stiffness, ductility, and bearing capacity of these joints were analyzed through the bending moment-rotation and load-displacement curves. The test results indicate that in addition to the low stiffness phase when the bolt contacts the screw hole at the initial loading stage, the stress process of bolted glulam joints were divided into elastic, crack, and failure stages. The staggered arrangement of bolts improve the bending and tensile bearing capacity and ultimate deformation of beam-column joints and beam joints: the yield bending moment and tensile yield load increase by about 35% and 7.1% respectively, compared to the beam-column joints and beam joints in square bolt arrangements. For the staggered bolted joints, the deformation of beam-column joints in the plastic stage is small. The ductility coefficient is about 71% of that of the squared bolted beam-column joints. The staggered bolted beam joints have better plastic deformation and ductility. The tensile ductile coefficient is 2.79 times that of squared bolted beam joints.关键词:glulam;beam-column joints;beam joints;slotted-in steel plate;bolted connection;loading capacity;rotational behavior;failure mode- 58

- |

- 10

- |

- 0

发布时间:2023-10-07 -

摘要:A novel soybean protein-sucrose based adhesive (DSF/SADP) was made of defatted soybean protein (DSF), sucrose, and ammonium dihydrogen phosphate (ADP). The effects of mass of solid components, the mass ratio of defatted soybean protein to sucrose and ammonium dihydrogen phosphate solution, the synthesis temperature, and the synthesis time on the bonding strength of the adhesive were investigated. The optimum synthesis process of the adhesive was as follows: mass of solid components of 70%, the mass ratio of defatted soybean protein to sucrose and ammonium dihydrogen phosphate 1∶4, the synthesis temperature of 70 ℃, the synthesis time of 3 h, when the hot pressing temperature was 170 ℃ and the hot pressing time was 7 minutes, the wet bonding strength of the three-layer plywood was 0.99 MPa. The results of thermal gravimetric analysis (TG) and differential scanning calorimetry (DSC) showed that DSF/SADP adhesives possibly accompanied by polycondensation during thermal degradation. The results of infrared spectroscopy and microscopic morphology showed that 5-hydroxymethylfurfural or its derivatives participated in the cross-linking reaction; and the formed C-O-C was the main bond of the cured polymer; the cured adhesive with DSF reduces the diameter of the surface holes and provides a denser surface.关键词:Soy protein;sucrose;ammonium dihydrogen phosphate;adhesive;plywood

摘要:A novel soybean protein-sucrose based adhesive (DSF/SADP) was made of defatted soybean protein (DSF), sucrose, and ammonium dihydrogen phosphate (ADP). The effects of mass of solid components, the mass ratio of defatted soybean protein to sucrose and ammonium dihydrogen phosphate solution, the synthesis temperature, and the synthesis time on the bonding strength of the adhesive were investigated. The optimum synthesis process of the adhesive was as follows: mass of solid components of 70%, the mass ratio of defatted soybean protein to sucrose and ammonium dihydrogen phosphate 1∶4, the synthesis temperature of 70 ℃, the synthesis time of 3 h, when the hot pressing temperature was 170 ℃ and the hot pressing time was 7 minutes, the wet bonding strength of the three-layer plywood was 0.99 MPa. The results of thermal gravimetric analysis (TG) and differential scanning calorimetry (DSC) showed that DSF/SADP adhesives possibly accompanied by polycondensation during thermal degradation. The results of infrared spectroscopy and microscopic morphology showed that 5-hydroxymethylfurfural or its derivatives participated in the cross-linking reaction; and the formed C-O-C was the main bond of the cured polymer; the cured adhesive with DSF reduces the diameter of the surface holes and provides a denser surface.关键词:Soy protein;sucrose;ammonium dihydrogen phosphate;adhesive;plywood- 61

- |

- 9

- |

- 0

发布时间:2023-10-07 -

摘要:The changes in final moisture content, residual stress, and visible defects were examined on four import wood species and one domestic species for solid wood flooring after hygrothermal equalization treatment for disinfestation (D process) and sterilization (S process) by using a conventional wood dryer. The results showed that the quality of flooring planks was varied in different tree species of the same batch. After the treatment, the moisture content deviation in and between flooring planks was reduced; the moisture content uniformity was improved; the moisture content in thickness decreased; and the residual stress was reduced. In addition, changes in the visible defects can be ignored. Consequently, the determined D process (65 °C and 73.8% to 89.5% relative humidity) and S process (75 °C and 76.7% to 91.2% relative humidity) met the temperature requirements of the hygrothermal process for disinfestation or sterilization, as well as the drying quality improvement of flooring planks. The drying quality of the treated flooring planks met the requirements of the standard LY/T 2058—2022 "Blanks for solid wood flooring" and the 2nd grade in GB/T 6491—2012 "Drying quality of sawn timber".关键词:plank for solid wood flooring;disinfestation;sterilization;hygrothermal equalization treatment;drying quality;Residual stress

摘要:The changes in final moisture content, residual stress, and visible defects were examined on four import wood species and one domestic species for solid wood flooring after hygrothermal equalization treatment for disinfestation (D process) and sterilization (S process) by using a conventional wood dryer. The results showed that the quality of flooring planks was varied in different tree species of the same batch. After the treatment, the moisture content deviation in and between flooring planks was reduced; the moisture content uniformity was improved; the moisture content in thickness decreased; and the residual stress was reduced. In addition, changes in the visible defects can be ignored. Consequently, the determined D process (65 °C and 73.8% to 89.5% relative humidity) and S process (75 °C and 76.7% to 91.2% relative humidity) met the temperature requirements of the hygrothermal process for disinfestation or sterilization, as well as the drying quality improvement of flooring planks. The drying quality of the treated flooring planks met the requirements of the standard LY/T 2058—2022 "Blanks for solid wood flooring" and the 2nd grade in GB/T 6491—2012 "Drying quality of sawn timber".关键词:plank for solid wood flooring;disinfestation;sterilization;hygrothermal equalization treatment;drying quality;Residual stress- 57

- |

- 8

- |

- 0

发布时间:2023-10-07 -

摘要:To improve the mechanical properties of wood-plastic composites (WPCs), in this study, a thermally reversible covalent crosslinked WPCs (TRC-WPCs) was prepared based on transesterification reaction using wood flour (WF), E-51 epoxy resin, and phthalic anhydride as raw materials through the hot-pressing process. The effects of epoxy/anhydride molar ratio, hot-pressing parameters, and cyclic reprocessing on the mechanical properties of TRC-WPCs were investigated. The optimum molar ratio of epoxy to anhydride was 1∶1. The optimal hot-pressing parameters of TRC-WPCs were as follows: hot-pressing time of 30 min, temperature of 150 ℃, and pressure of 12 MPa. The tensile strength, tensile modulus, flexural strength, and flexural modulus of TRC-WPCs prepared with the optimal formulation and hot-pressing process were 47.3 MPa, 9.3 GPa, 79.2 MPa and 8.9 GPa, respectively, which were 282%, 204%, 305%, and 245% higher than those of the WF/HDPE (high-density polyethylene, HDPE) composites with the same WF content. The retention rate of flexural strength and modulus after cyclic reprocessing was 67.8% and 84.2%. The TRC-WPCs can be permanently crosslinked at service temperatures and efficiently plasticized at high temperatures, showing remarkable mechanical properties and reprocessability.关键词:thermally reversible covalent crosslinked wood-plastic composites (TRC-WPCs);epoxy vitrimer;reversible covalent bonding;cyclic reprocessing;hot-pressing process;mechanical properties

摘要:To improve the mechanical properties of wood-plastic composites (WPCs), in this study, a thermally reversible covalent crosslinked WPCs (TRC-WPCs) was prepared based on transesterification reaction using wood flour (WF), E-51 epoxy resin, and phthalic anhydride as raw materials through the hot-pressing process. The effects of epoxy/anhydride molar ratio, hot-pressing parameters, and cyclic reprocessing on the mechanical properties of TRC-WPCs were investigated. The optimum molar ratio of epoxy to anhydride was 1∶1. The optimal hot-pressing parameters of TRC-WPCs were as follows: hot-pressing time of 30 min, temperature of 150 ℃, and pressure of 12 MPa. The tensile strength, tensile modulus, flexural strength, and flexural modulus of TRC-WPCs prepared with the optimal formulation and hot-pressing process were 47.3 MPa, 9.3 GPa, 79.2 MPa and 8.9 GPa, respectively, which were 282%, 204%, 305%, and 245% higher than those of the WF/HDPE (high-density polyethylene, HDPE) composites with the same WF content. The retention rate of flexural strength and modulus after cyclic reprocessing was 67.8% and 84.2%. The TRC-WPCs can be permanently crosslinked at service temperatures and efficiently plasticized at high temperatures, showing remarkable mechanical properties and reprocessability.关键词:thermally reversible covalent crosslinked wood-plastic composites (TRC-WPCs);epoxy vitrimer;reversible covalent bonding;cyclic reprocessing;hot-pressing process;mechanical properties- 73

- |

- 18

- |

- 0

发布时间:2023-10-07 -

摘要:Double drum knife ring flaker is one of the indispensable equipment for material preparation section of particleboard production. When the width of the knife ring increased, uneven wearing loss in the width direction of the knife ring of the double drum knife-ring flaker became significantly. According to the principle of blocking and diverting, a dividing device with a shape of double 8 was designed, which was mainly composed of a primary dividing plate, a secondary dividing plate, a connecting rod, and a driving shaft. The effects of the bending Angle of the dividing wing and the speed of the dividing device on the motion trajectory of the wood chip were analyzed by computational fluid dynamics (CFD). The results showed that the installation of the dividing device make the wood chip distribute evenly in the width direction of the knife ring, which is helpful in solving the problem of uneven wearing loss of the knife ring. The research results provide a theoretical basis and technical support for the development of the double drum knife ring flaker.关键词:double drum knife knife-ring flaker;dividing device;CFD;simulation analysis

摘要:Double drum knife ring flaker is one of the indispensable equipment for material preparation section of particleboard production. When the width of the knife ring increased, uneven wearing loss in the width direction of the knife ring of the double drum knife-ring flaker became significantly. According to the principle of blocking and diverting, a dividing device with a shape of double 8 was designed, which was mainly composed of a primary dividing plate, a secondary dividing plate, a connecting rod, and a driving shaft. The effects of the bending Angle of the dividing wing and the speed of the dividing device on the motion trajectory of the wood chip were analyzed by computational fluid dynamics (CFD). The results showed that the installation of the dividing device make the wood chip distribute evenly in the width direction of the knife ring, which is helpful in solving the problem of uneven wearing loss of the knife ring. The research results provide a theoretical basis and technical support for the development of the double drum knife ring flaker.关键词:double drum knife knife-ring flaker;dividing device;CFD;simulation analysis- 36

- |

- 11

- |

- 0

发布时间:2023-10-07 -

摘要:In response to the problem of low production efficiency and mainly relying on manual labor in the production of wood structural component, A programmable logic controller (PLC) automatic control system was proposed to control the truss type robotic arm fitted vacuum sponge suction cups for loading and unloading palletizing operation,the automatic loading and unloading palletizing device for wood structural component was designed and developed. The test of handling Chinese fir wood structural component with a size of 2 387 mm× 118 mm× 152 mm (length×width×height) showed that the efficiency of loading and unloading was 187 pieces/hour. The qualified rate of loading and unloading was 99.4% and 99.2%, respectively. The results showed that the automatic loading and unloading equipment for wood structural component is stable and efficient, which fully meet the technical requirements of loading and unloading operation for wood structural component.关键词:wood structural component;automatic loading and unloading;vacuum adsorption system;automatic control

摘要:In response to the problem of low production efficiency and mainly relying on manual labor in the production of wood structural component, A programmable logic controller (PLC) automatic control system was proposed to control the truss type robotic arm fitted vacuum sponge suction cups for loading and unloading palletizing operation,the automatic loading and unloading palletizing device for wood structural component was designed and developed. The test of handling Chinese fir wood structural component with a size of 2 387 mm× 118 mm× 152 mm (length×width×height) showed that the efficiency of loading and unloading was 187 pieces/hour. The qualified rate of loading and unloading was 99.4% and 99.2%, respectively. The results showed that the automatic loading and unloading equipment for wood structural component is stable and efficient, which fully meet the technical requirements of loading and unloading operation for wood structural component.关键词:wood structural component;automatic loading and unloading;vacuum adsorption system;automatic control- 33

- |

- 8

- |

- 0

发布时间:2023-10-07

RESEARCH PAPERS

-

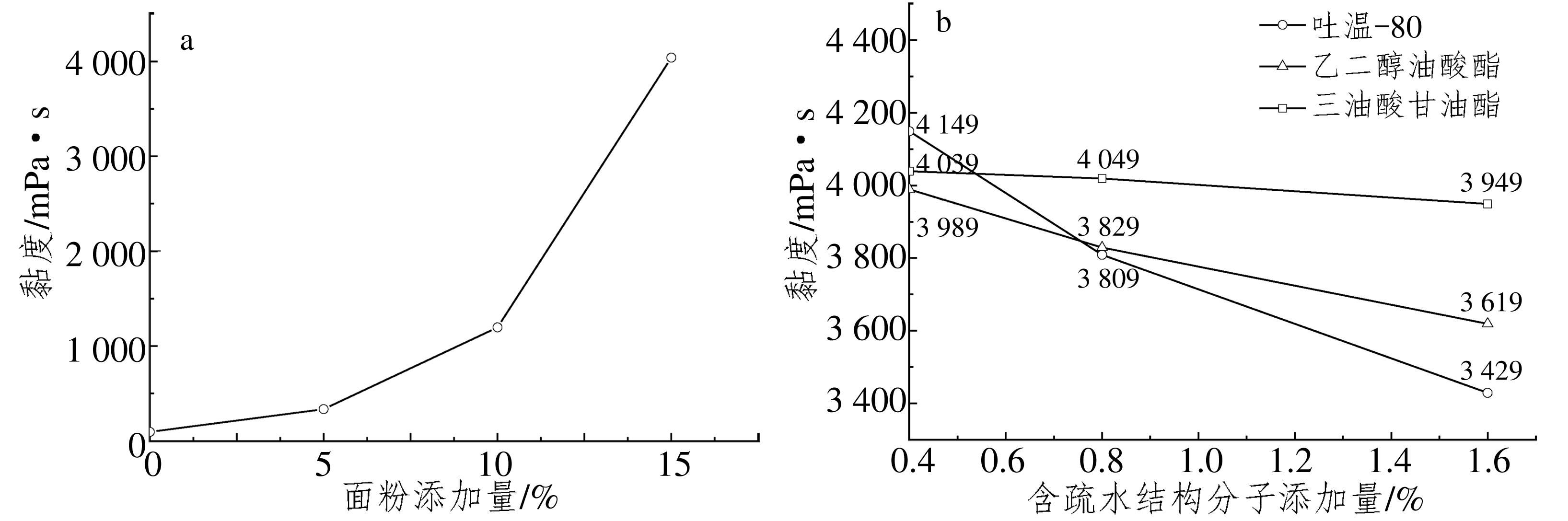

摘要:The viscosity of the glue increased rapidly when the modified urea-formaldehyde resin combined with flour at the sprinkling process of manufacturing plywood. It significantly affects the uniformity of the adhesive layer. This study proposed a method to control the viscosity of the glue by diluting the association between the glue components with the molecules containing hydrophobic groups (ethylene glycol oleate, triolein, and Tween-80). The effects of the molecules containing hydrophobic groups on the viscosity and the change rate of the glue were discussed. Results show that when the amount of Tween-80 which was non-ionic surfactant was 1.6% of the glue mass, the viscosity of the glue decreased from 4 039 mPa·s to 3 429 mPa·s. Within 0.5~5.5 hours after mixing, the average increase rate of the glue viscosity reduced by 74% compared to the control group. The hydrophilic end of the molecules containing hydrophobic groups which were non-ionic surfactant ensures its uniform dispersion in the glue. The association between the components of the glue was effectively diluted by the hydrophobic end of the non-ionic surfactant. In addition, when the amount of non-ionic surfactant was appropriate, the bonding strength of the plywood prepared with the corresponding adhesive was higher than that of the control group. However, an excessive addition of the additive led to a decrease in the bonding strength of the plywood.关键词:modified urea formaldehyde resin adhesive;viscosity;sprinkling adhesive;association interactions;non-ionic surfactant

摘要:The viscosity of the glue increased rapidly when the modified urea-formaldehyde resin combined with flour at the sprinkling process of manufacturing plywood. It significantly affects the uniformity of the adhesive layer. This study proposed a method to control the viscosity of the glue by diluting the association between the glue components with the molecules containing hydrophobic groups (ethylene glycol oleate, triolein, and Tween-80). The effects of the molecules containing hydrophobic groups on the viscosity and the change rate of the glue were discussed. Results show that when the amount of Tween-80 which was non-ionic surfactant was 1.6% of the glue mass, the viscosity of the glue decreased from 4 039 mPa·s to 3 429 mPa·s. Within 0.5~5.5 hours after mixing, the average increase rate of the glue viscosity reduced by 74% compared to the control group. The hydrophilic end of the molecules containing hydrophobic groups which were non-ionic surfactant ensures its uniform dispersion in the glue. The association between the components of the glue was effectively diluted by the hydrophobic end of the non-ionic surfactant. In addition, when the amount of non-ionic surfactant was appropriate, the bonding strength of the plywood prepared with the corresponding adhesive was higher than that of the control group. However, an excessive addition of the additive led to a decrease in the bonding strength of the plywood.关键词:modified urea formaldehyde resin adhesive;viscosity;sprinkling adhesive;association interactions;non-ionic surfactant- 82

- |

- 9

- |

- 0

发布时间:2023-10-07

RESEARCH BRIEFING

- 摘要:The Chinese national standard GB/T 18513—2022 “Names of main woods imported into China”, which was revised based on GB/T 18513—2001, was issued on December 30th, 2022, and officially effected on July 1st, 2023. This paper briefly introduces the revision process and principles of the standard, and focuses on the main changes of contents including the scope and names of wood species. It aims to provide guidance and reference to the users to properly understand and apply the standard.关键词:imported wood;wood name;national standard;family;genus;species

- 174

- |

- 23

- |

- 0

发布时间:2023-10-07

DISCUSSION ON STANDARDS

0